The project

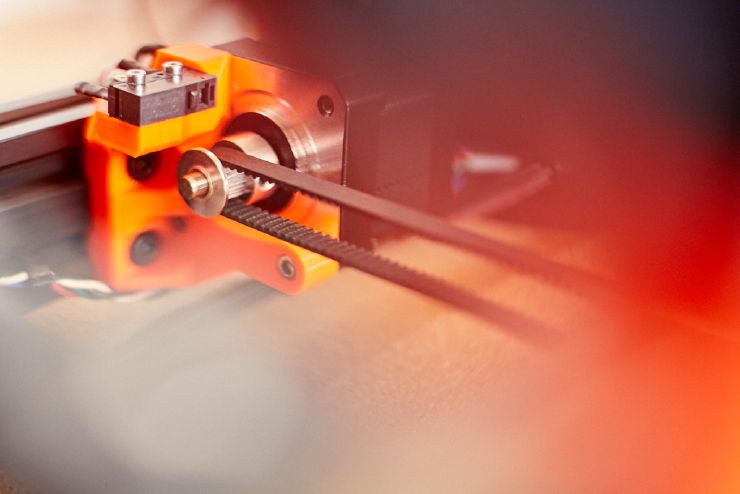

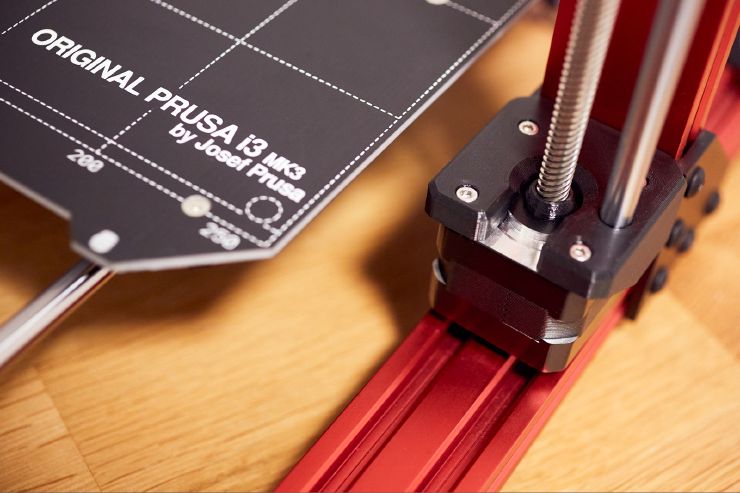

The Bear Frame is an upgrade for the Original Prusa i3 MK2(S), MK2.5(S)(S+) and MK3(S)(S+) 3D printers. It improves rigidity, reliability, enables faster printing, increases precision, makes maintenance easier and opens the door to more customisation. Plus it looks unique with the coloured extrusions!

Features

- Compatible with Original Prusa i3 MK2(S), MK2.5(S) and MK3(S)(S+)

- Compatible with lots of extruders like Original Prusa, BearExxa, BearMera (E3D Hemera) and Bondtech Prusa Upgrade

- Reuse of as many parts as possible

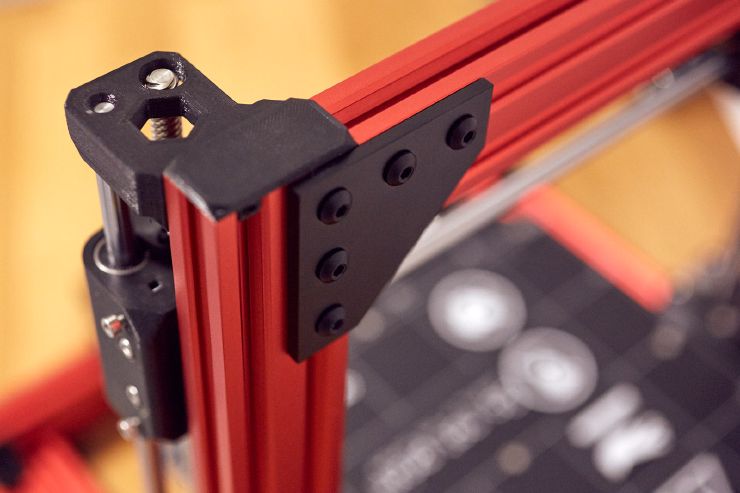

- Sturdy frame for faster printing

- High quality extrusions

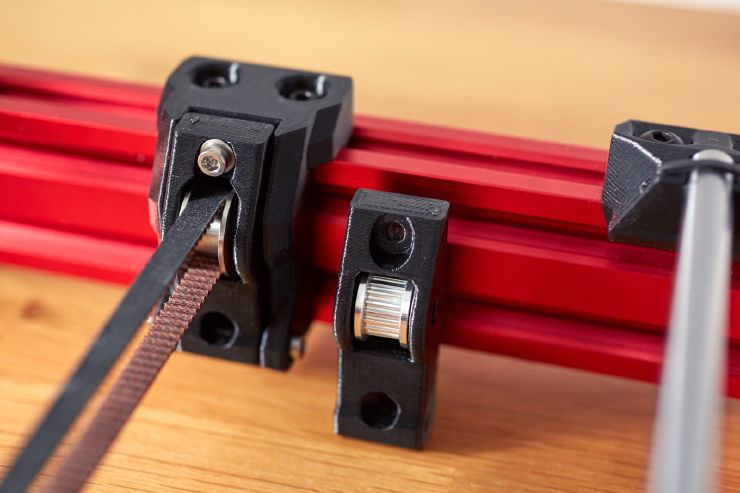

- Custom, sturdier t-nuts

- Improved accuracy

- Reduced noise level

- Easy to use and maintain

- Built to last

- Uses open source V-Slot aluminum extrusions

- Thoroughly tested development

- Highly customisable

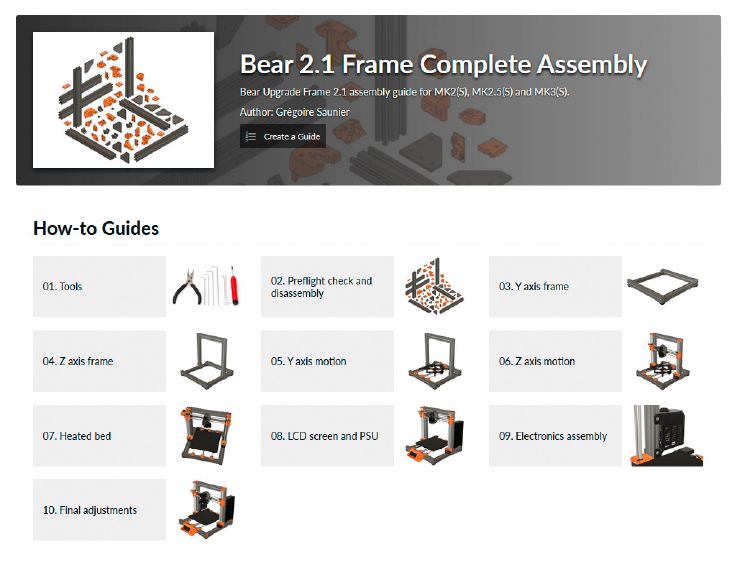

- Detailed documentation

- Truly open source

Designed with care

Safety

As the designer of a robot that melts flammable plastic, I’ve always felt responsible for making the product correctly and safely. This means being transparent with the customer, complying with regulations (e.g. CE, UL), testing everything carefully, supporting the customer and providing detailed assembly and safety instructions.

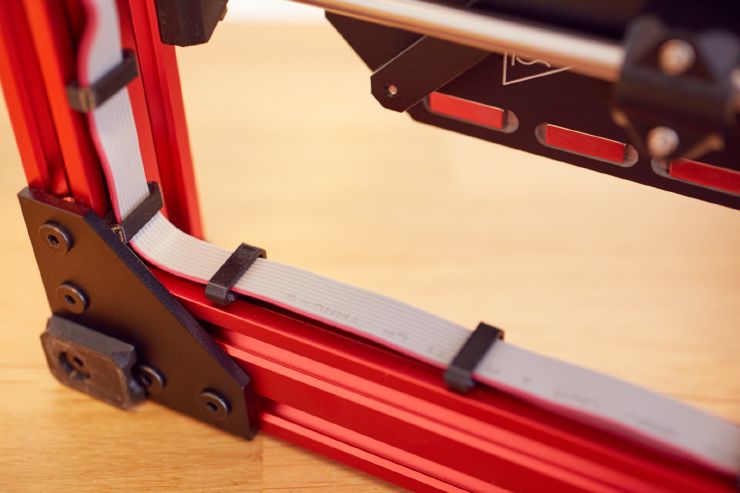

Screenshot of the assembly guide

Screenshot of the safety guides

Open source hardware

Careful design also involves adhering to the open source rules as the Prusa i3 was1 an open design. The Bear frame is certified by the Open Source Hardware Association.

OSHWA Certification ID

This project was my first experience with open source hardware and it was and still is a fruitful experience. I was able to gain a lot of knowledge quickly, improve the product thanks to the close relationship with the community and share ideas with other open source projects. It also makes the product easy to repair and sustainable, values that are very important to me. Working in the open is not just about releasing the files, it is also a precious mental attitude and culture.

Recycled plastic

In developing Bear Frame Upgrade 2.1, I decided to use only recycled PETG plastic. After some testing, I found that rPETG produced by Mitsubishi (under various brand names) was very similar to standard PETG and would not affect my design process or the printer’s performance. This filament is made from 100% recycled post-industrial plastic and contains a small amount of pigment for colouring. It is still my go-to filament today.

History

In 2017, I bought my first 3D printer, a Prusa MK2S. While I was impressed with the capabilities of 3D printing, I realised that the frame was not very rigid and could be improved. As many have experienced, designing a 3D printer is addictive and so the passion has grown quickly!

In September 2017, I released the Bear Frame Upgrade 1.0. At that time it was only half a frame as the aim was to replace the threaded rods at the base with aluminium extrusions. 3 days later Prusa announced the new MK3, which improved the frame in a similar way 😁 !

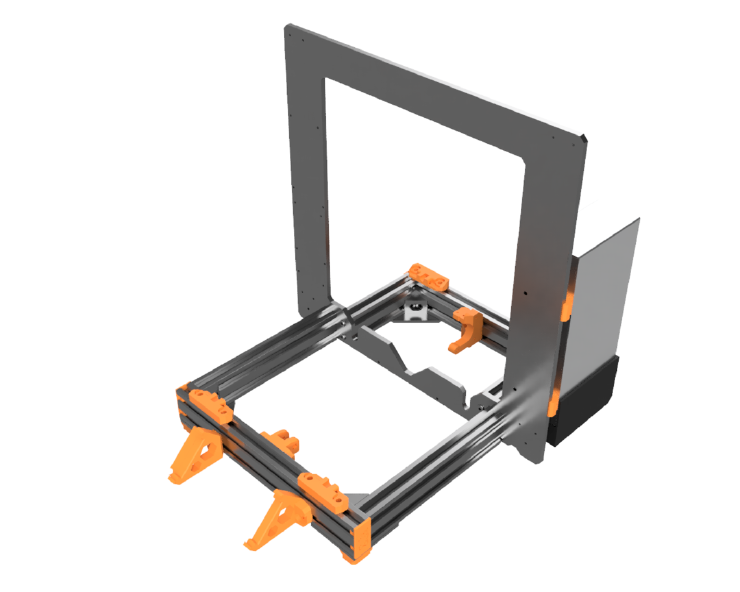

Rendering of the Bear Frame 1.0 with the 6 extrusions and the printed parts in orange

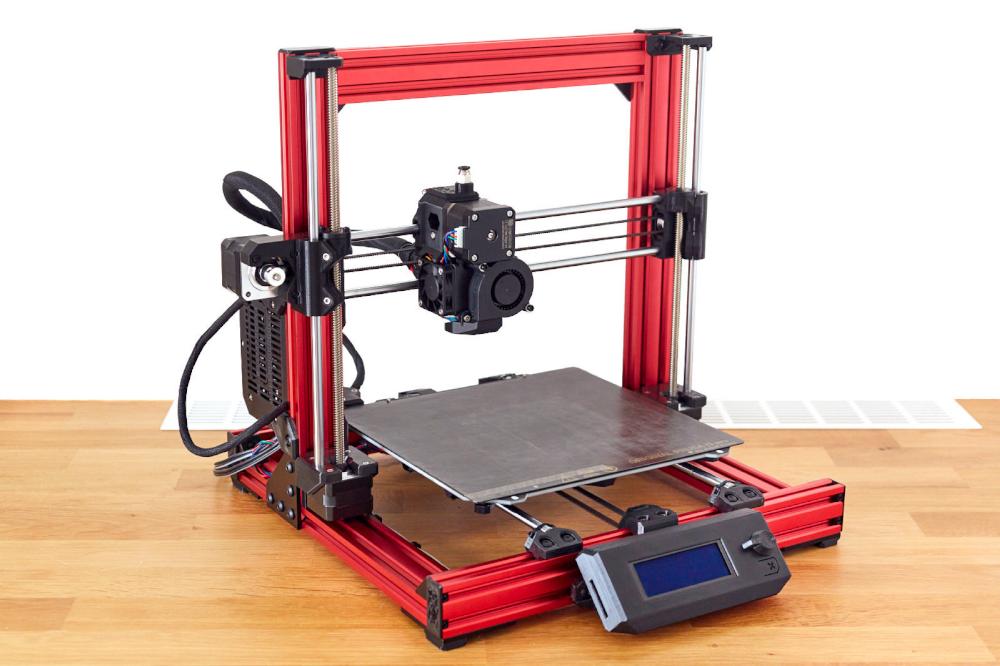

MK2S with the Bear Frame 1.0

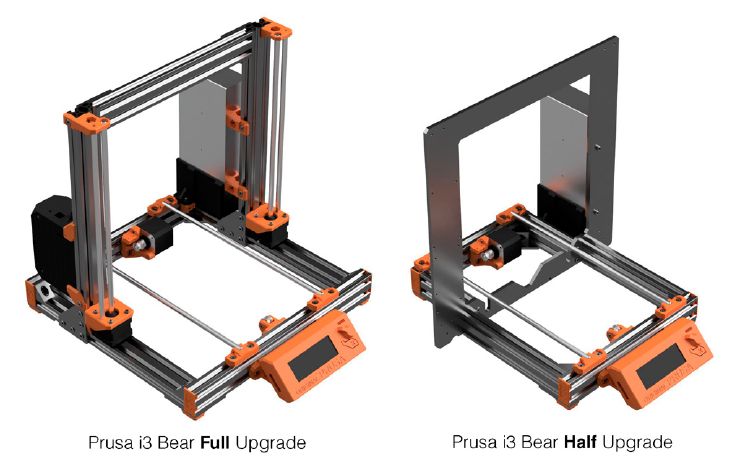

In the beginning of 2018, the Bear Frame Upgrade 2.0 was released and it was adding extrusions on the Z axis, eliminating the entire Prusa frame. This design improved stiffness and made it possible to have a very square frame. The MK3 was compatible and I decided to keep the half upgrade in this version for retro compatibility and a lower price option.

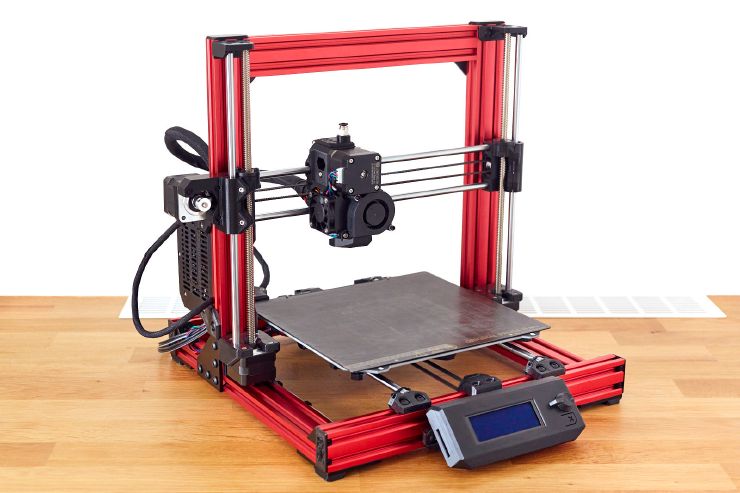

Half and Full Bear Frame Upgrade 2.0

Bear Frame Full Upgrade 2.0 MK2.5S

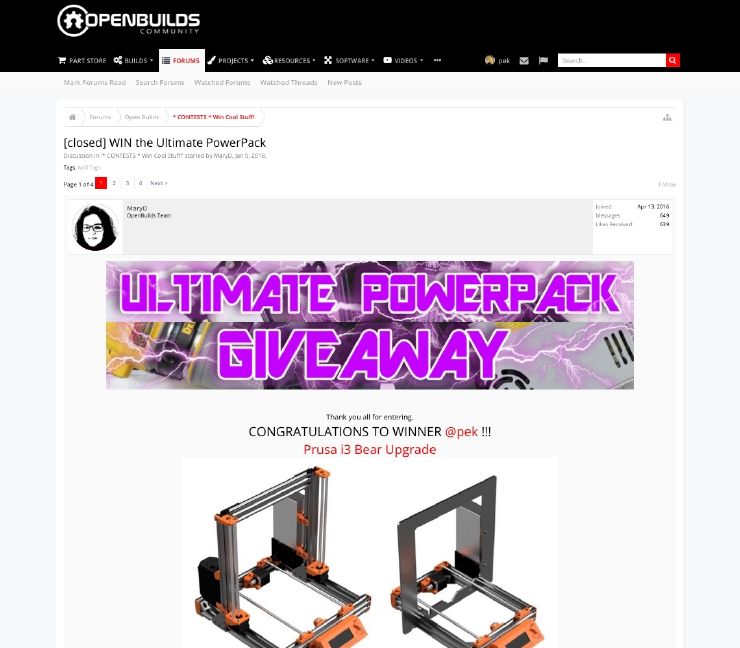

In March 2018, the Bear Frame Upgrade 2.0 won the the Openbuilds’ “Ultimate Powerpack Giveaway” contest.

The Bear Frame won an Openbuilds contest

It was during this year that I partnered with the first resellers2 around the world to make a kit available to anyone who didn’t have the tools to make one. At first, the kit was built entirely from parts that the reseller bought himself, but this ended up being difficult for customers due to variations in quality. Later I met Jason Yiming Bao, CEO of LDO Motors, and we decided to make a unique official kit. Jason surprised me by making coloured extrusions (annodised) and it was a superbe idea!

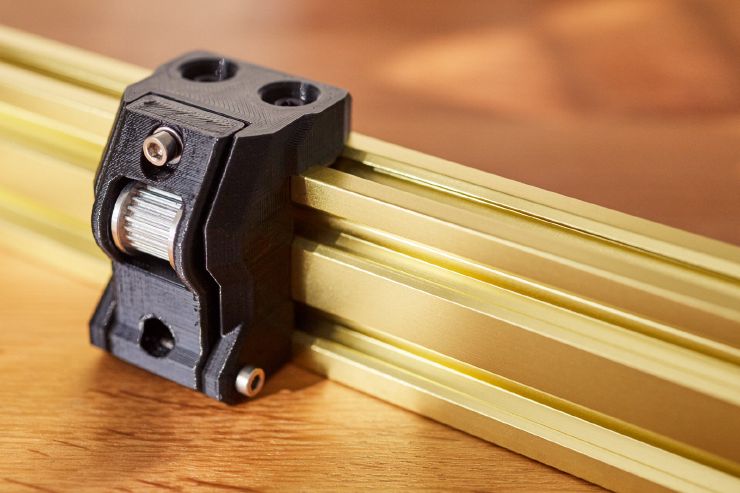

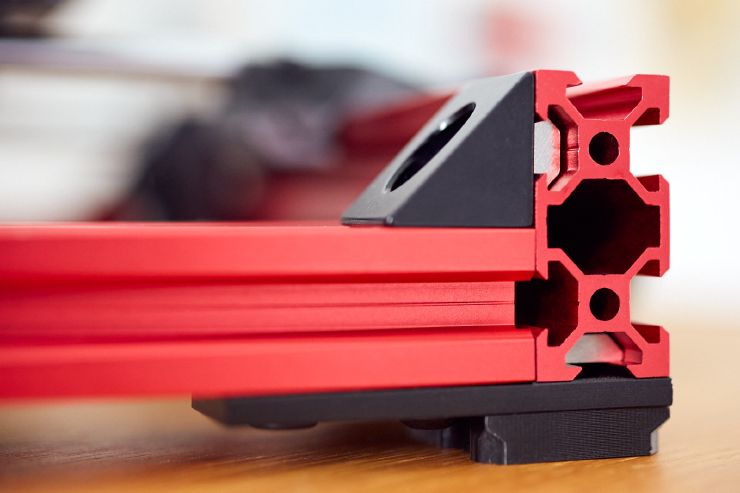

Colored V-Slots by LDO Motors. (Photo by Lecktor.com)

We also looked for the best possible hardware to improve the quality. We couldn’t find any good and reasonably priced T-nuts, so we decided to make our own open source stainless steel ones.

Open source custom Bear T-nuts

In April 2022, I released the Bear Frame Upgrade 2.1 which increased the stiffness thanks to stronger printed parts and introduced the new open source T-nuts. The new parts also made assembly easier and the guide was much improved. The half frame was dropped and a single design was compatible with all Prusa i3 versions.

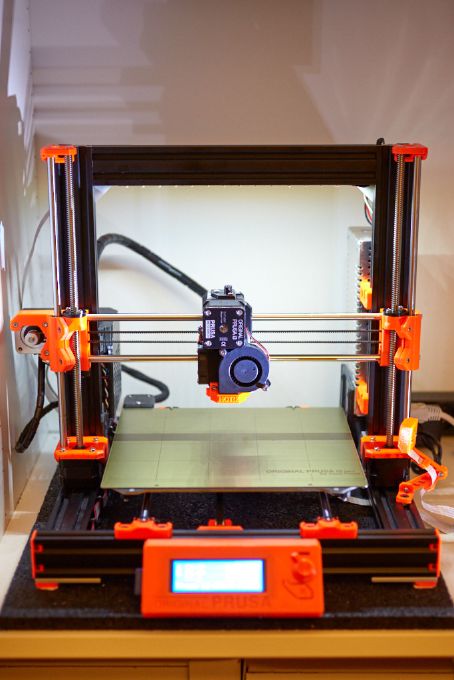

Bear Frame Upgrade 2.1 MK3S+

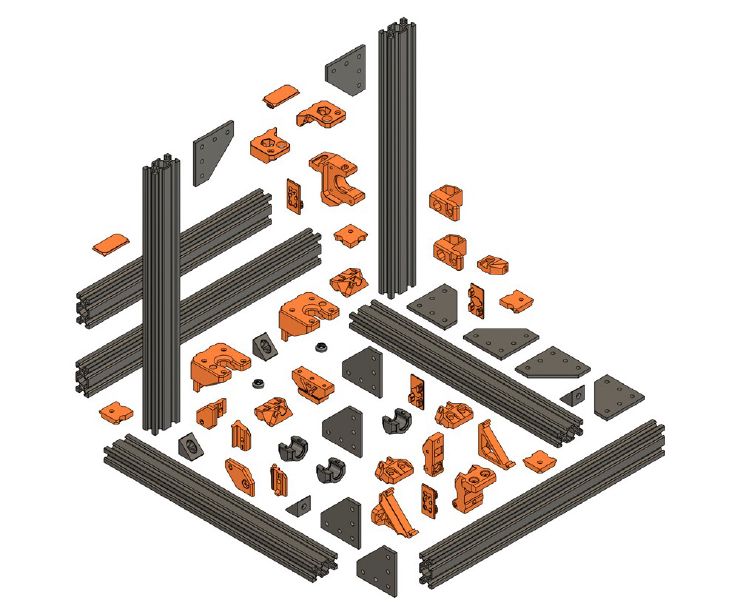

Exploded view of the Bear Frame Upgrade 2.1 parts

Thank you to

- all makers that have built a Bear

- my Patreon’s for their support

- Bendix Sørensen, David Ogles, Florian Däubler, Jason from LDO Motors, Paul Skapczyk, Nathan Denkin, Sleene, Josh Jones and Stefan Maue for helping me with the development

- all the official distributors2 for taking care of the kits

- LDO Motors team for their work

- all that have sent me a tip

- all the good chats on social networks

- all forks and contributions

- Openbuilds for your hardware, community and state of mind

- Open Source Hardware Association for their resources and support

- Adrian Bowyer for having invented RepRap

♥️

Links

Official repository (GitHub)

Other links

- Assembly guides on bear-lab.com

- Open Source Hardware Certification

- Bear Frame Upgrade 2.0 on Openbuilds

- Bear Frame Upgrade 1.0 on Openbuilds

- Bear Frame Upgrade 2 .0 on Thingiverse

- Bear Frame Upgrade 1 .0 on Thingiverse

Gallery

GitHub issue #158 Native Source Files (Autodesk Inventor), article When Open Becomes Opaque: The Changing Face of Open-Source Hardware Companies by Adafruit, articles A(nother) Reply to Josef Průša and What Does an Open Source Hardware Company Owe The Community When It Walks Away? by Michael Weinberg, articles A reply to Josef Průša and Prusa Has Learned Nothing by Stargirl, article With Core ONE, Prusa’s Open Source Hardware Dream Quietly Dies by Hackaday. ↩︎

Over the years, the Bear has been sold by the following official resellers: 3D Boom (EU), All3DMakers (USA), Blackfrog (EU), Lecktor (EU), Makerparts (CA), Ooznest (UK), Printed Solid (USA), RatRig (EU). By its open source nature it was also sold through other stores in the world. ↩︎ ↩︎