The project

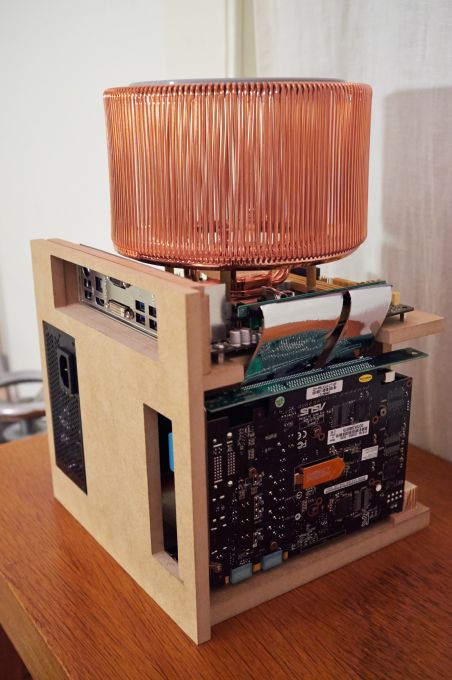

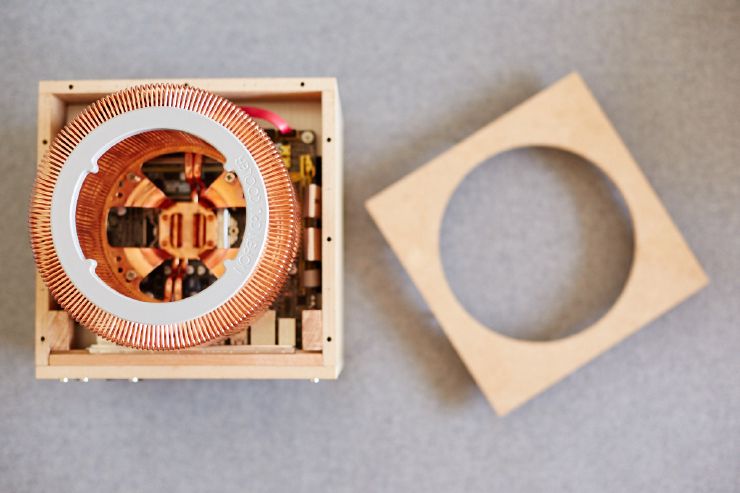

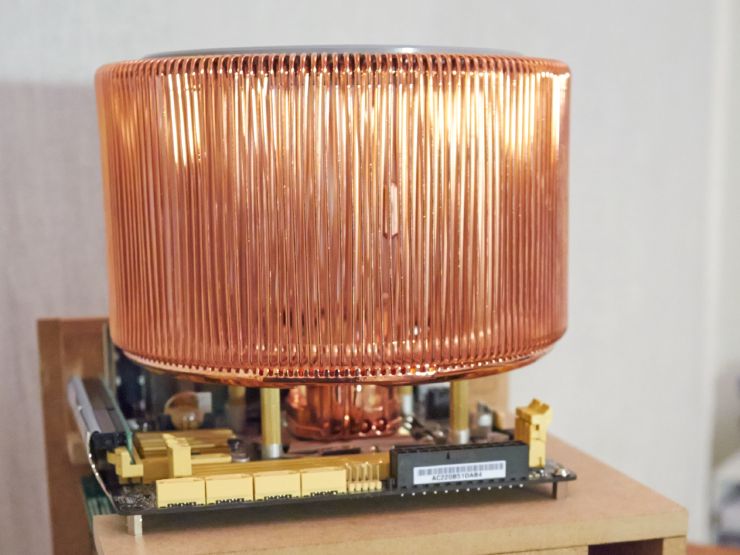

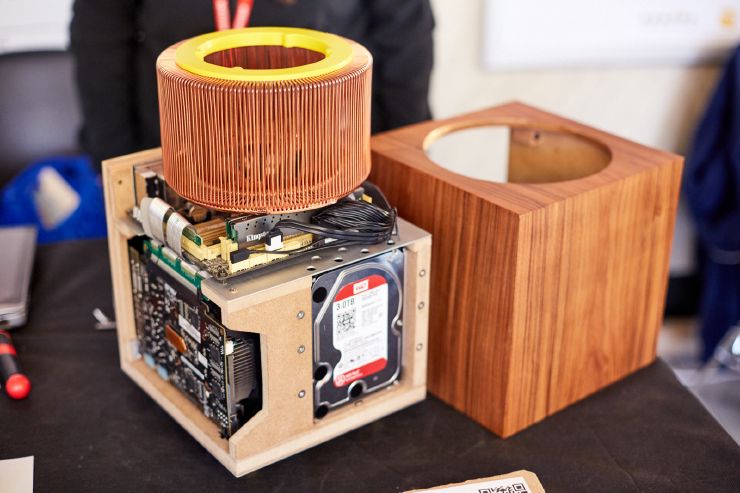

When I first saw the Nofan CR-95C fanless CPU heatsink, I laughed at its size and appearance! But few days after, I started finding it more and more aesthetic. I thought it would make a great looking computer if it was visible outside the case and paired with wood.

Nofan CR-95C heatsink on a Mini-ITX motherboard

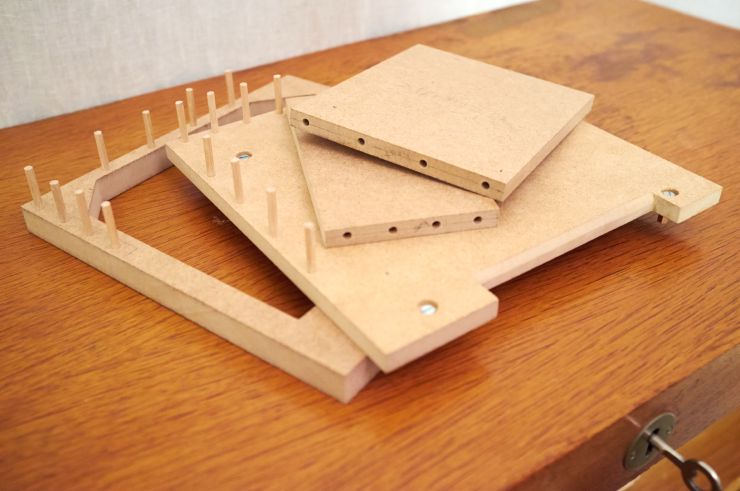

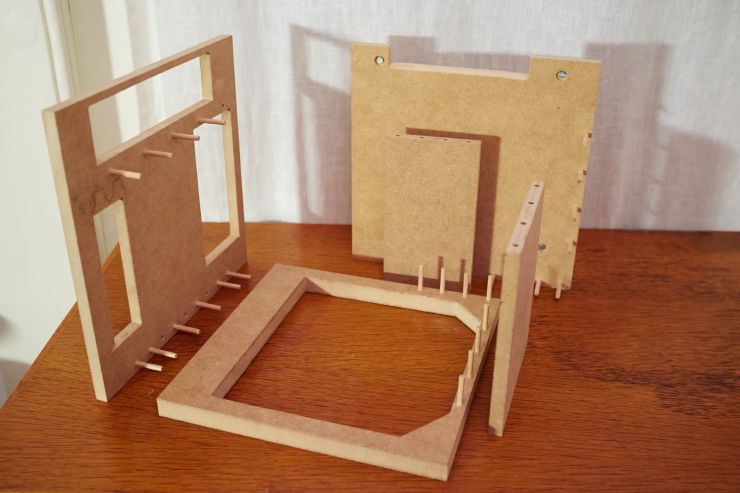

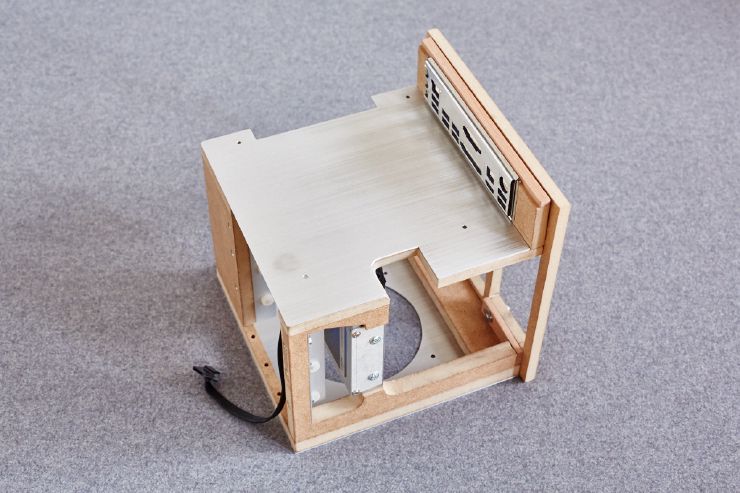

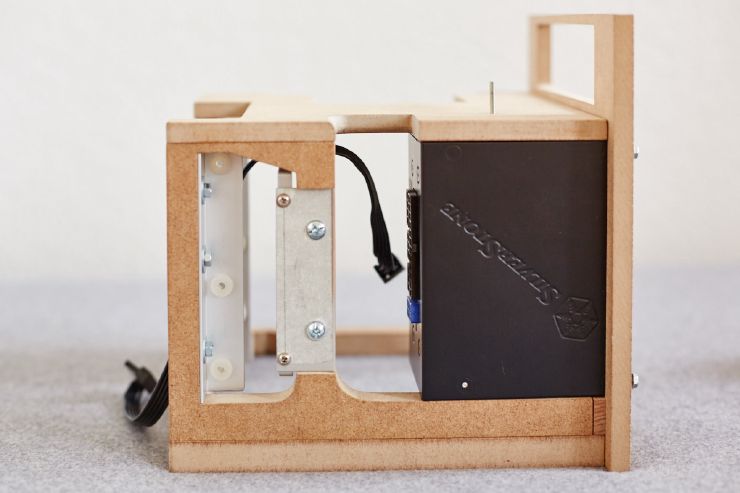

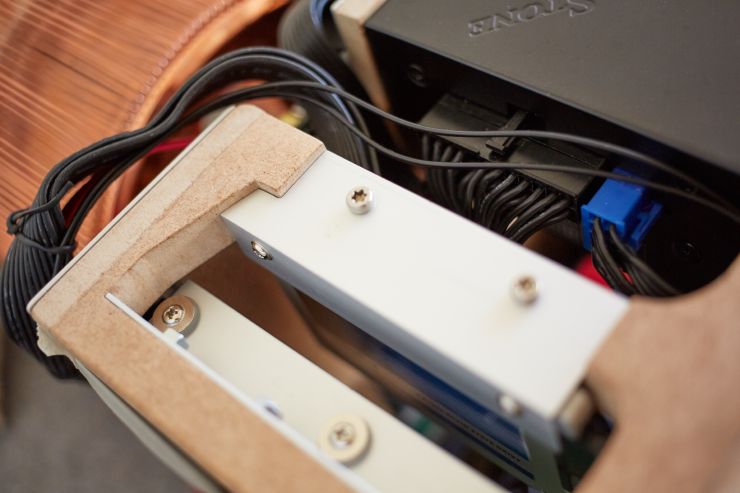

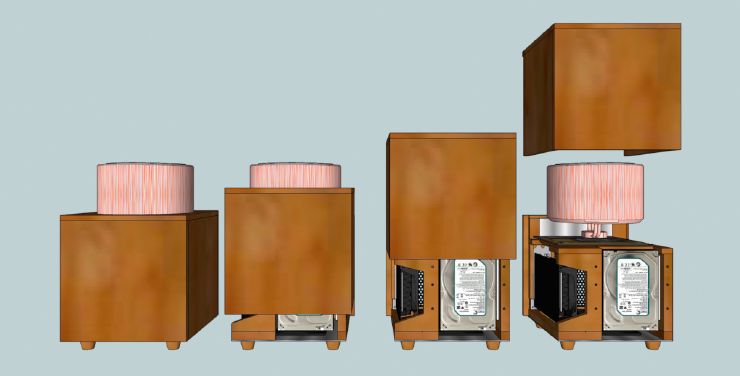

I started the design in 2014, opting for a cube shape to contrast with the rounded shape of the heatsink and to have enough space to install the hardware inside. The external dimensions of the wooden cube are 23x23x23 centimetres, which is quite small when you have to fit all the components inside, along with the best possible silent cooling. To solve this 3D puzzle, I spent many hours in Sketchup, a 3D modelling software I was using at the time.

CAD view showing how the case is getting opened

CAD view of the inside

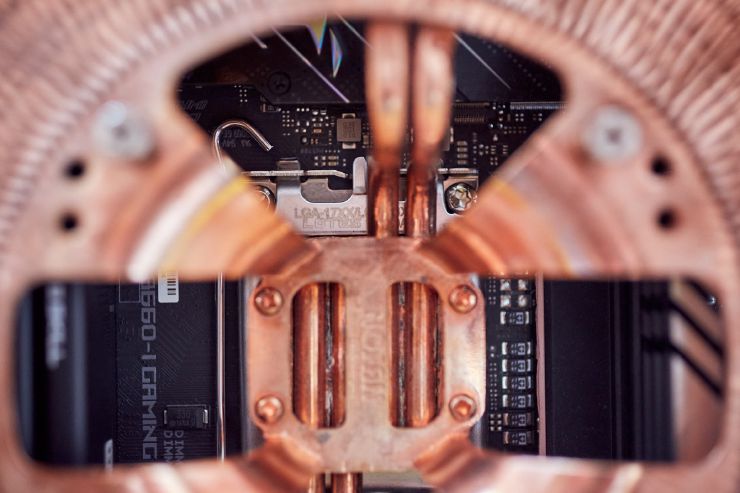

This case has the limitation of only accepting a motherboard with the CPU in exactly the same position. Fortunately, in 2022, I was able to replace the CPU with a 12th generation Intel Core i7, thanks to Asus, which hasn’t changed the location of the socket in 8 years! Obviously, the heatsink wasn’t designed for this generation, but it still covers the IHS perfectly and the CPU doesn’t go over 60°C (tested with Cinebench)! What an impressive cooler Nofan has made!

In the wild

The great fanlesstech.com website shared the progress of my build in 2014. It was later nominated “Mod of the Month April 2015” along with 6 other projects on the famous bit-tech.net site. Finally, it was presented during the LemanMake in 2018, a local Maker Faire.

Nominated ‘Mod of the Month April 2015’ by bit-tech.net

Materials

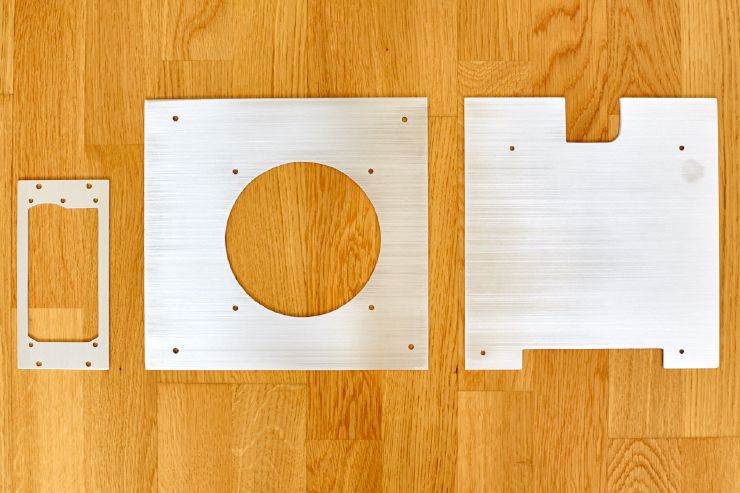

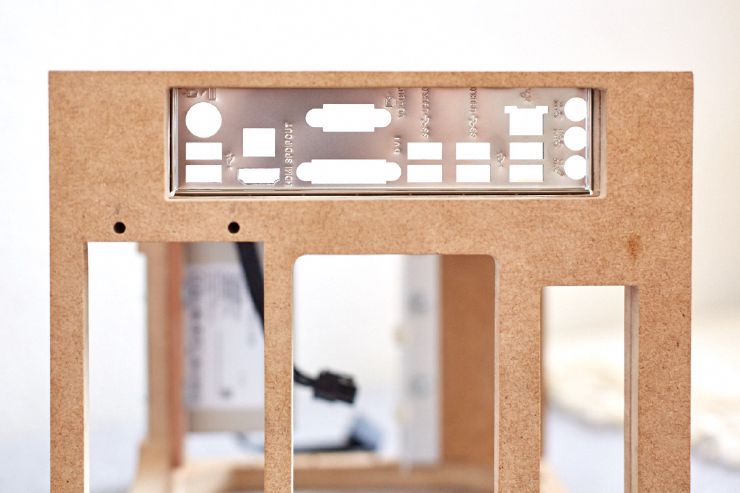

The wood is MDF (medium density fibre) to ensure stability throughout the year with constant heating and cooling cycles. Later I covered it with rosewood veneer. Some structural parts are aluminum and the feet are 3D printed in PETG.

The result

It’s my main computer and I use it every day. It has enough power for my tasks, it’s super quiet and I’m still not bored of the way it looks.

Build gallery

Some images of the build.